There are various hologram productiontechnologies. There are two basic directions to consider. On the one hand, classic holography in the sense of "writing with light" in a substrate - on the other hand, the "holographic projection" of an image or film onto a special display. We deal with the production of embossed holograms. You can get to know the basics here in brief descriptions.

Before a hologram can be produced in its final form, a so-called master must be created, which is the "mother" of all subsequent production steps.

The master is the key to the quality and application of the hologram. This is where the form in which the light is projected into the holographic film is decided. All the properties of the hologram are defined in a holographic master.

Our hologram stickers, security labels and other holographic products are manufactured with the highest precision and resolutions from 24,000 dpi to 637,000 dpi in 4 different security levels. In addition to the unique design for our customers, holograms with your own logo offer ideal counterfeit protection in combination with an individual quality seal for your brands and products.

With our individual and counterfeit-proof hologram stickers, security labels, high-quality hologram foils, seal closures, transfer foils, void labels with Tamper Evident, shrink films and other high-quality products, we reliably protect your product against tampering and counterfeiting, enhance it visually and give the customer confidence to stand out in the POS displays (point of sale) and convey security.

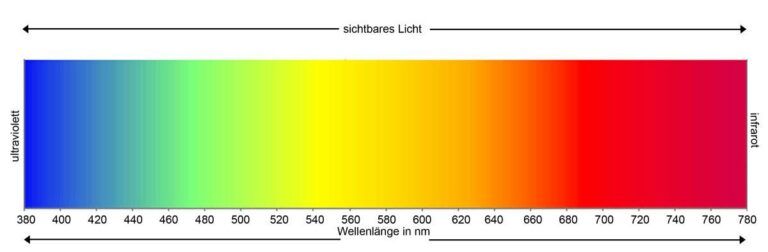

A hologram sticker consists of a relief structure that reflects incident light at certain wavelengths. This relief structure is exposed by a highly complex laser mastering system in a photoreactive film, from which the so-called embossed shims are then created by various galvanic forming processes, with which the holographic microstructure can be transferred to a carrier layer.

A hologram sticker is not printed, but embossed and is always an exact copy of the unique structure of the master. A hologram sticker is therefore forgery-proof and can be used in a variety of ways as a seal for product protection and brand protection.

Hologram stickers are equipped with numerous individual security features that protect your brand.

We achieve the high security level of our hologram stickers through counterfeit-proof embossing with the highest laser mastering resolutions available worldwide.

Your individual hologram is processed into a unique embossing plate, with which your personal hologram stickers are produced and processed into security labels.

Either a real object or a computer-generated vector file is needed as a starting point.

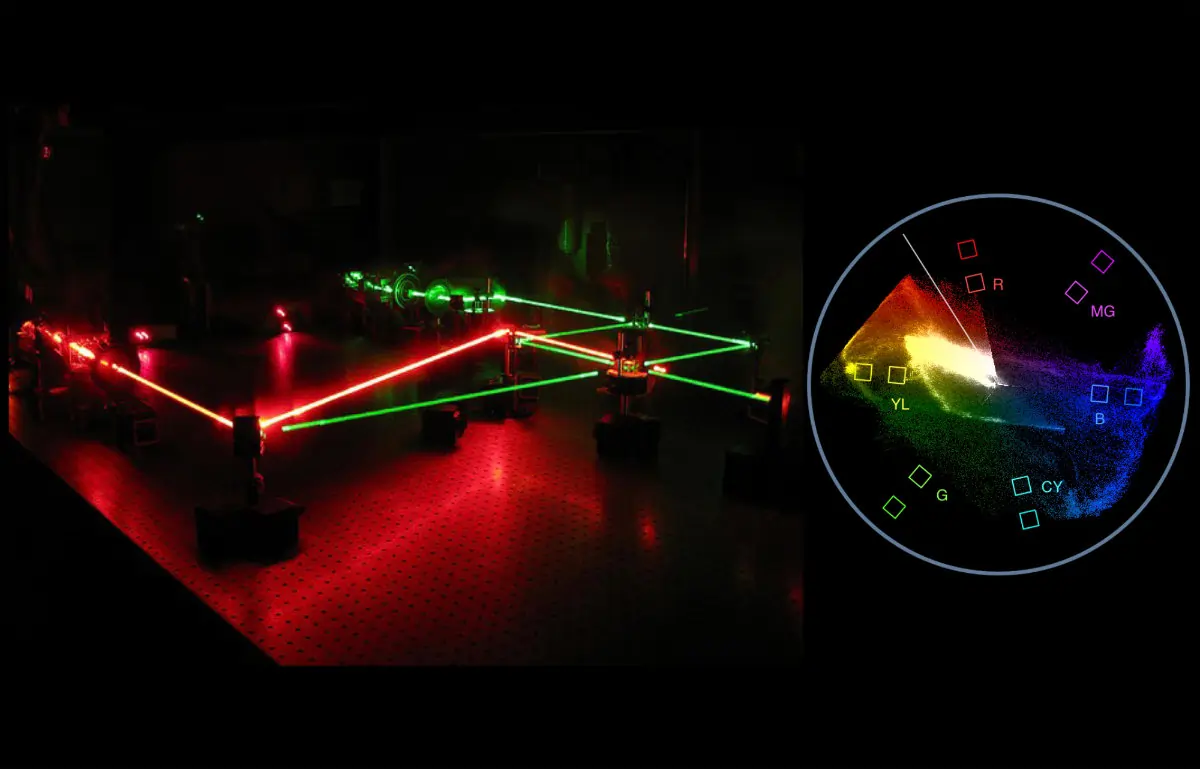

For recording, you need an absolutely dark room, several very powerful lasers in red, green and blue (for multicolor holograms due to additive color mixing) and an absolutely vibration-free workplace. The smallest vibrations can destroy a master recording. If the occurring interference waves shift e.g. only by 1/2 wavelength, wave trough and wave crest will cancel each other out in some places. The image would be destroyed. Some of the largest holographic masters for industrial film production were therefore exposed in cave systems underground.

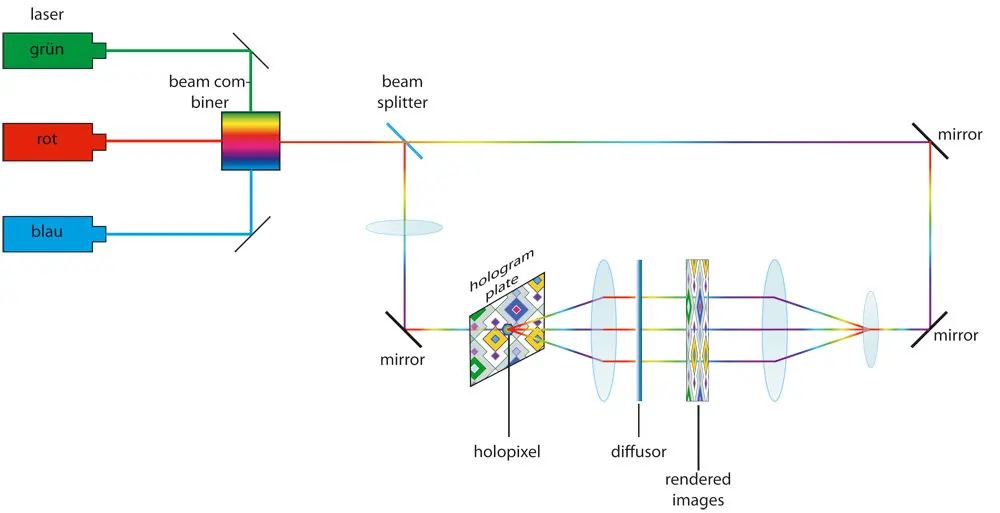

With the development of Dot-matrix exposure holography took a great leap forward. This technology makes it possible to expose computer-generated files, be they images, vector graphics or even short film sequences, in a holographic film. With this form of exposure, the silver halide film is exposed point by point using a laser and the original file is transferred to the holographic film. The standard resolutions here are 24,000 - 120,000 dpi.

However, much higher resolutions are possible with special exposure machines. The Nano Optical Imaging technology allows us to realize resolutions of up to 637,000 dpi.

The laser beam is split into two beams by a so-called beam splitter and deflected by different lenses and mirrors in such a way that one beam, the "reference beam" hits the holographic film (silver halide) directly and the second beam, the "object beam" hits the object placed in front of the film. The interferences, which are now imaged by the two beams on the holographic film, correspond exactly to the light, which is emitted by the object when we look at it with our eyes. It is therefore a 100% exact copy of the surface of the object.

After the film has been developed, if a light source is used from the same angle as the reference beam, the exact 3-dimensional image of the object can now be seen. Depending on the angle size, the object rotates around its own axis for the viewer and, for example, faces can be viewed from all sides, depending on the size of the shooting angle.

With the Nano Optical Imaging Hologram we offer the world's highest security level with unique holographic effects and microstructures, which we produce with a Resolution of up to 637,000 dpi image.

The laser has a line width of 10nm. This corresponds to 1/100,000 millimeter.

With the Dot Matrix Lithography Hologram we offer you 3 different security levels and can create structures with a Resolution of 24.000 up to 120.000 dpi image.

The RGB lasers, which are used for the exposure of the holographic master, enable a brilliant color reproduction of the holographic effects.

Holographic relief structures are best suited for industrial reproduction. To create these, the transmission master must be copied into a photoresist hologram using a special process. During the subsequent development process, the relief structure required for embossing reproduction is created in the photoresist film according to the partial exposure intensity.

The relief structure is excellently suited for producing so-called embossing shims (printing plates) from hardened metals via galvanic molding in a special tank. The surfaces of these shims are very resistant and are used to apply the molded relief structure to a desired substrate. Usually a plastic (PET, OPP, BOPP, PVC or coated paper) is used for this purpose. However, with special techniques it is also possible to transfer a hologram directly into other metals (e.g. gold, silver).

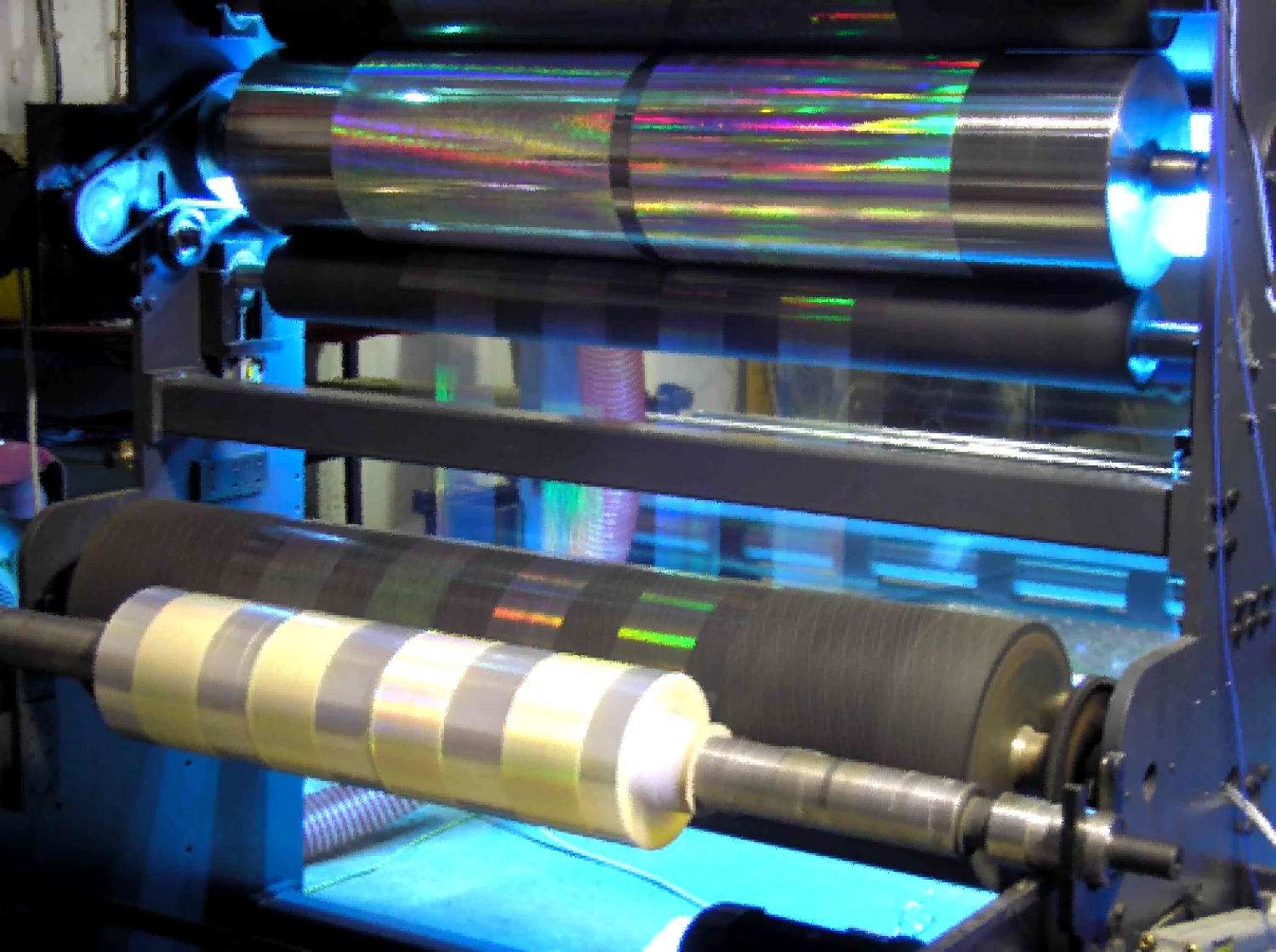

In order to be able to produce holograms in large quantities, the holograms are duplicated in a special recombining process to create an embossing shim that can be used in the embossing machines for the industrial production of holograms.

Embossed shims with different properties are required for the industrial production of holograms. The individual motif is recombined in the desired panel format so that the base material can be optimally utilized in the production process. Holographic register or cut marks can also be included in the process.

For the production of security holograms, a plastic film is usually used as a carrier material that can be thermomechanically embossed and has resistant properties in order to form a sufficiently firm surface that can reproduce the holographic relief structure well.

This film, usually made of coated PET, is embossed using a rotary process, equipped with a special adhesive on the back, applied to siliconized paper and finally delivered in the desired form.

The embossing of the hologram, in combination with various tamper-evident effects in the base material, creates a structure in the label that not only ensures counterfeit protection in the shaping of the relief structure, but also guarantees durability and protection against tampering when applied to the substrate in the event of attempts to remove it.

In the conventional recombining process the aim is to obtain a printing plate that can be used in so-called wide-web or narrow-web machines. The printing plates are placed around a cylinder, whereby a so-called "shimline" is created on the side where the plate ends meet, which is of course not a problem with individual motifs, but can be disruptive with continuous motifs and also leads to problems during further processing, e.g. in lamination processes in the packaging sector.

Seamless holographic decors (patterns) can be produced using a new technology in the film manufacturing process, which makes it possible to produce "seamless". These seamless hologram films can be processed much better and more efficiently in industrial applications.

CONTACT FORM

Would you like advice or a quote for your request? Write to us using our contact form:

Call back by phone? We will be happy to get back to you.

I am interested in :

Copyright © 2025 Holodimensions. The contents of these pages are subject to the rights of the author and are therefore protected.